How our services support the automotive industry

Due diligence

Supplier engagement is a critical aspect of supply chain due diligence. However, automotive companies often face difficulties when trying to obtain supply chain transparency data from their suppliers.

Through a combination of supplier engagement and data-driven contextualised ESG and CAHRA risk data, TDi enables you to gain a more comprehensive understanding of the risks in your supply chain. This approach is complemented by targeted auditing of higher risk suppliers.

Using TDi’s Digital Platform you can explore the ESG risk exposure of your specific individual suppliers, and view multiple tiers of your supply chain visually and geographically.

Regulations and standards mapping

With new mandates and guidelines emerging at both national and international levels every year around recycling, producer responsibility, labour and carbon emissions, to name a few, ensuring your company remains compliant can be overwhelming. TDi’s expertise and digital tools enables automotive companies to proactively map the regulations and standards that apply to their operations.

Case study: Helping an automotive company understand the voluntary standards landscape

Supply chain risk mapping

TDi can help you to identify the risks associated with the materials in your automotive supply chains – developing systems to measure and compare materials’ sustainability attributes. This includes developing practical methodologies to capture Life Cycle Assessment (LCA) data in alignment with your group-level targets related to greenhouse gas emissions, water reduction, waste elimination, circularity and material usage.

Case study: Lifecycle analysis for a leading automotive manufacturer

Human Rights Strategies

The TDi team carries out human rights due diligence assessment for specific materials in automotive supply chains. This leads to the identification of potential and actual adverse human rights impacts associated with the sourcing, production, use, re-use and disposal of these materials, providing actionable insights to mitigate risks and enhance human rights performance.

Engagement with ASM

Responsible artisanal mining can provide a dignified livelihood and serve as a driver for local development, a pillar of responsible sourcing. However, large parts of the artisanal and small-scale mining (ASM) sector are not being reached through existing certification schemes and barriers still exist to direct, responsible sourcing.

TDi has been working with The Impact Facility (TIF) for Responsible Mining Communities and the Fair Cobalt Alliance for many years to help bring responsible ASM supply of critical minerals to the market. Responsible Mineral Credits (RMCs) such as TIF’s Cobalt Credit scheme, provide an opportunity for the automotive industry to invest in responsible ASM.

Insight> Opportunity for the automotive industry to invest in responsible ASM

Insights & Reports

TDi’s data analysts and responsible sourcing experts produce insight reports and data-driven research and analysis for a wide range of clients.

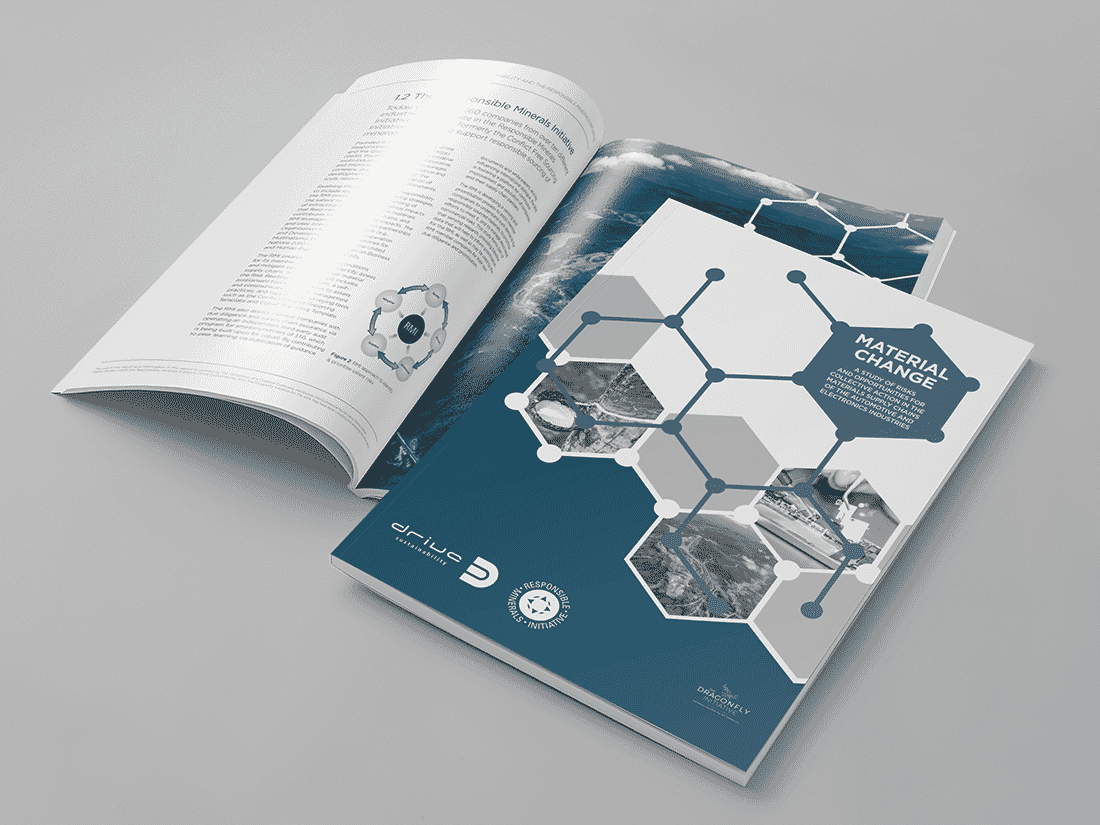

Case study: Material Change – a study assessing the materials used in automotive and electronics supply chains

TDi is known for its knowledge and data on ESG risks in minerals and metals supply chains – enabling industry-wide comparisons of ESG issues and their significance in the automotive industry. Get in touch with your research requirements.

Latest Trends

Increasing regulatory demand

Adhering to substance bans, recycling standards and policies like the EU Battery Regulation, requires an in-depth regulatory knowledge and insight. By understanding these shifting demands, automotive manufacturers and suppliers can remain compliant and position themselves for long-term success.

Lack of supplier engagement

Supplier engagement is a critical aspect of supply chain due diligence. Poor responsiveness is a key issue, together with the limitations of relying solely on audits to gain this information. This blocks downstream companies from identifying upstream suppliers, and therefore from addressing supply chain risks.

Limited supply chain data access

Automotive (and overall downstream) companies often face difficulties when trying to obtain supply chain transparency data from their suppliers. This blocks downstream companies from addressing the supply chain risks increasingly required by regulations.

Data lock-in and poor interoperability of data solutions

With many different suppliers in complex supply chains, it can it can be difficult to view data from multiple suppliers in one place. It can be challenging to migrate data between different digital tools, making it difficult to build a complete picture of ESG risk. TDi’s Supply Chain & Due Diligence Tool provides a complete visual map and exportable data repository for your entire supply chain.

Circular economy and recycling

Automotive companies face rising expectations to use recycled materials and implement circular principles throughout their entire supply chain. TDi can help your organisation ensure it will meet its future needs for secondary materials, and that these materials are responsibly sourced.

Key Resources

Material Change report

This report produced by TDi, Drive Sustainability and RMI, provides a study of risks and opportunities for collective action in the materials supply chains of the automotive and electronics industries.

Material Change Report

"*" indicates required fields

Automotive industry

Case studies

Meet TDi’s automotive industry experts

Other services and tools supporting the automotive industry

Your project

made possible