The Pathway to Net Zero: Shaping the Future of the Luxury Sector

The luxury sector, particularly the textile and fashion industries, is witnessing a significant shift towards sustainability and circularity. In recent years, increased consumer awareness and stricter regulations have propelled a radical transformation, with the sector becoming more conscious of its overall environmental footprint.

The fashion and textile industries have profound impacts on sustainability, including significant contributions to greenhouse gas emissions, water depletion, pollution, waste, and habitat destruction, and are often linked to human rights abuses. While emerging solutions aim to address these impacts, barriers such as lack of awareness, resistance to change, and economic constraints impede their implementation.

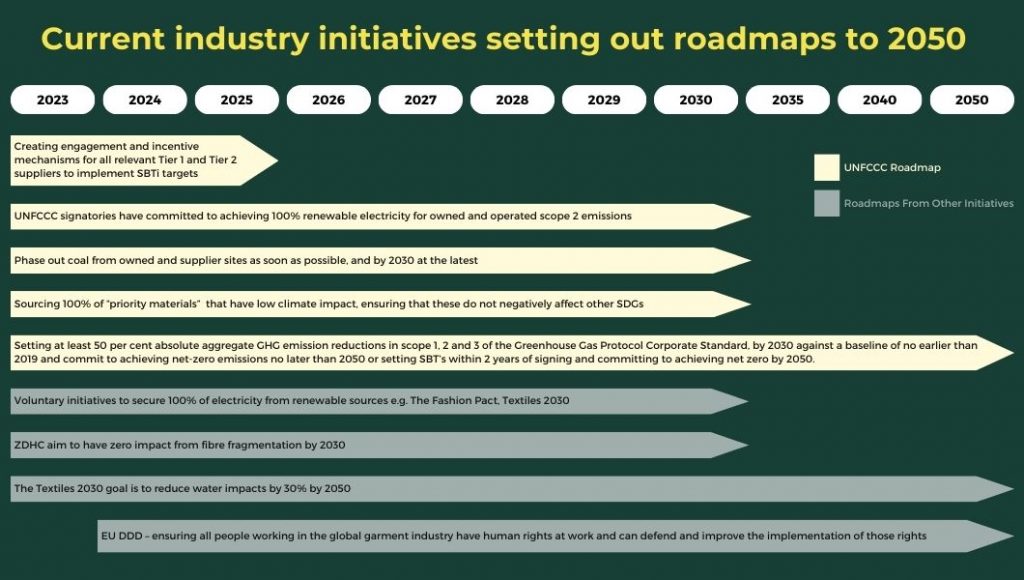

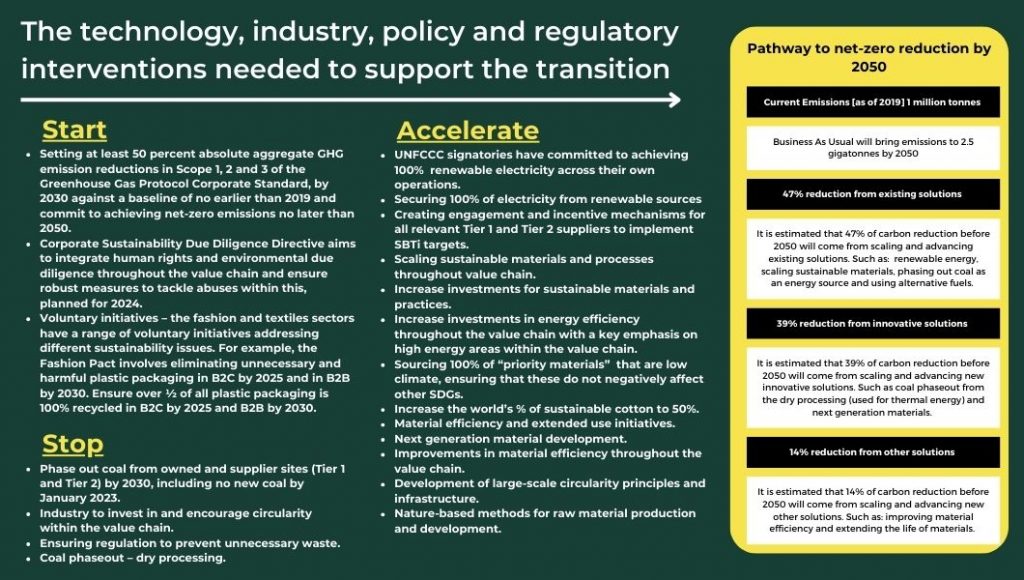

Businesses will need to align with the United Nations Fashion Industry Charter for Climate Action in order to achieve net-zero emissions by 2050.

Challenges in the Fashion and Textile Industries

Carbon Emissions

The fashion and textiles industries were responsible for 1.025 Gt of CO2 in 2019, roughly 2% of greenhouse gas emissions. This could increase to 5.66 Gt by 2030 if left unchecked and would not meet the 45% reduction required by the Paris Climate Agreement.

Water and Chemical Usage

Fibre production, dyeing and finishing require fresh water, which can lead to deterioration of groundwater levels and water scarcity. Wastewater is released into water systems containing dye, inorganic finishing agents, chlorine compounds and heavy metals. High water temperatures reduce dissolved oxygen levels in the water and can lead to an imbalance of biodiversity.

Natural Habitat Destruction

Cotton is the most used non-synthetic fibre in the world. Farming of cotton is insecticide and pesticide-intensive: although cotton grows on only 2.4% of global croplands, it accounts for 22.5% of the world’s insecticide use.

Wood-based natural fibres/artificial cellulose fibres (MMCFs) are created from cellulose, mainly derived from wood. It is estimated that over 150 million trees are logged annually for MMCFs, and up to 30% of MMCFs may come from endangered and primary forests.

Fibres

Textiles are a major source of microplastic pollution, specifically microfibres. Microfibres are emitted into the oceans through effluent wastewater by manufacturing operations, apparel-wearing, and disposal processes. It’s estimated that textiles contribute to 35% of microplastics reaching the ocean. Today, around two-thirds of textile items produced are polymers and are ingested and incorporated into food webs, damaging marine ecosystems and, eventually, human health.

Complex Supply Chains

Complex supply chains generally lack visibility across tiers 2 to 4. Raw material and manufacturing facilities are often ‘invisible’, with brands unable to implement sustainability programmes without reliable and accurate data. As a result, inaccurate, misleading information and lack of sustainability data across the value chain lead to potential greenwashing claims, inadequate sustainability programs, and unmitigated risks across the value chain.

Landfill

Globally, people use an estimated amount of 80 billion new articles of clothing per year, and approximately 73% of clothing is calculated to be incinerated or sent to landfill, with only 12% of textile waste downcycled and less than 1% recycled. Landfill sites release pollutants into local surroundings and contribute to habitat destruction, losing 30-300 species per hectare at each landfill site development.

Human Rights

Companies outsource their production processes in order to minimise cost, resulting in poor working conditions that violate health and safety standards, inadequate wages, trade union bans, abuse, harassment, and child labour.

Textile Trends

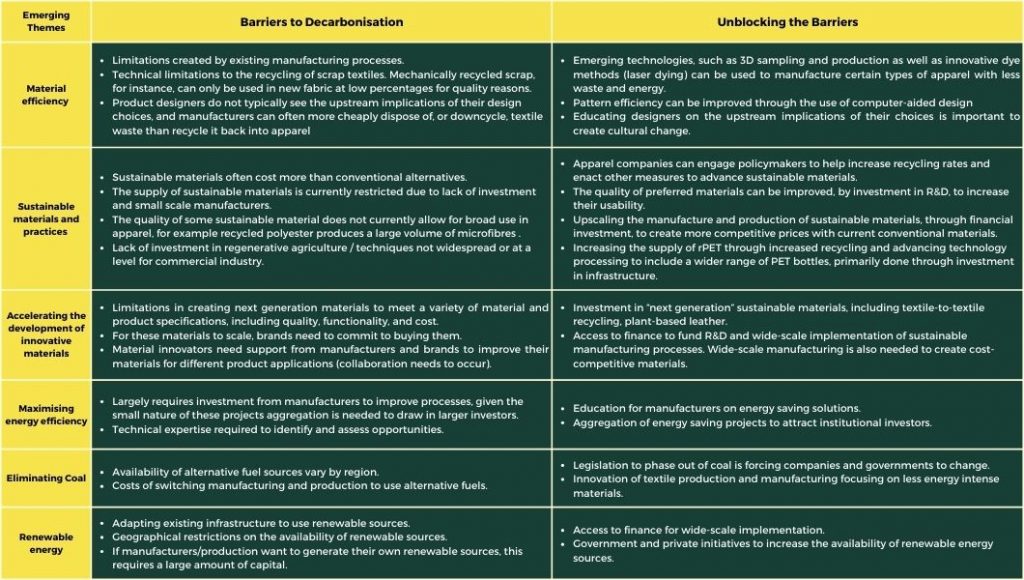

1. Maximising Material Efficiency

Efficiency is now a key consideration in material usage. With a focus on research, design and technology, the industry aims to minimise production waste and enhance material efficiency.

2. Scaling Sustainable Materials and Practices

The industry is witnessing increased usage of sustainable materials like recycled polyester and adopting sustainable practices such as conservation tillage for cotton. These initiatives are not only eco-friendly but also cost-effective in the long run.

3. Accelerating the Development of Innovative Materials

With an emphasis on durability and biodegradability, there’s a surge in investments for next-generation materials. These innovative materials, often incorporating recycled materials, are touted as the future of the industry.

4. Maximising Energy Efficiency

The textile industry incorporates energy-saving measures and new technologies to manage energy inefficiencies. Special software tools that provide visibility over energy spending and building usage are becoming increasingly popular.

5. Eliminating Coal in Manufacturing

Aligned with the UN Fashion Industry Charter for Climate Action, the textile sector is working towards eliminating coal from its manufacturing processes. It aims to run on 100% renewable energy by 2030 and achieve net-zero emissions by 2050.

6. Shifting to 100% Renewable Electricity

The Fashion Pact and Textiles 2030 are just some of the initiatives aiming for 100% renewable energy usage. These initiatives are indicative of the industry’s commitment to sustainability.

Fashion Trends

1. Consumer Sentiment

Increased consumer awareness about the environmental and social impact of fast fashion is leading to the rise of slow fashion. This model prioritises localisation and regionalism, reducing the industry’s carbon footprint.

2. Move Towards Circularity

The industry is witnessing a push towards a more circular economy, aiming to ensure all garments are reused, recycled, or biodegradable. The drive towards this model is evident in initiatives like Textiles 2030.

3. Increased Reporting, Disclosure and Supply Chain Due Diligence Policies

There is increased disclosure by firms around policies and commitments, usually highlighted through reporting and auditing processes. Continuous accountability from businesses highlights the importance of responsible sourcing in supply chains.

4. Improved Labelling and Value Chain Transparency

There is a push towards labelling information around the textile production process in order to increase transparency for consumers, with the help of tools such as the upcoming Textile Digital Product Passport.

Progress Needs Collaboration

The luxury sector’s journey towards a sustainable future is gaining momentum, propelled by consumer sentiment, regulatory changes, and technological advancements. As businesses align with the principles of the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement, a greener future can be obtainable by 2050. To achieve this ambitious target, industry and governing bodies need to work collaboratively and harness emerging technologies and innovation.

This collaboration will accelerate the transition of the fashion and textile industries towards sustainability, as they are not standalone entities; they depend on other sectors such as energy, technology, waste, plastic and chemicals, finance, and natural capital. Therefore, accelerating sector-wide progress towards a net-zero and nature-positive system will facilitate knowledge-sharing and collaboration across these industries.

Actors within the luxury sector need to take corrective and proactive action through the review, identification and remediation of existing supply chain processes and the development of new materials and practices. For these changes to occur, the sector needs to prioritise environmental and social issues, collaborate within and across sectors, and leverage existing and emerging technology. The future of these industries hinges on their ability to adapt to the changing environmental and social landscape and their commitment to a sustainable future.

supply chain

supply chain

Responsible sourcing of sand and silicates | Identifying and mitigating the hidden risk in your supply chains

24th June 2025 supply chain

supply chain

Responsible sourcing of critical minerals for the clean energy transition – The Asian context

6th June 2025 Industry Initiatives

Industry Initiatives