Webinar Recording: Can Bio-Based Plastics Scale Sustainably?

Bio-based plastics represent a potential alternative to the use of fossil fuels in the traditional plastics supply chain. However, the upscaling of bio-based plastics faces challenges, including concerns over competition with food production, a lack of consumer understanding of bioplastics, and difficulties achieving cost competitiveness with traditional plastics.

A project team of four – Patrice Barnett, Reino A. Hyyppa, Grace Reynolds, Kelsie Roberton – Master of Environmental Management students at the Duke University Nicholas School of the Environment, partnered with TDi Sustainability to explore these challenges and assess the potential for the sustainable scaling of bioplastics production.

After conducting desk-based research and interviewing ten stakeholders in the bio-based plastics space (producers, buyers, certification services, and non-governmental organizations), the Duke University team identified key focus areas for bio-based plastic supply chain stakeholders, to foster sustainability.

This webinar, which took place on Tuesday 18th April – 3pm BST, was an opportunity to explore and learn from the team’s findings and discover insights on the potential upscaling of bioplastics with sustainability at the core.

Watch the webinar now:

Read the webinar transcript:

Graham Lee

By introduction for those attending, I see quite a few are coming in now. My name is Graham Lee. I’m the head of research at TDi Sustainability. For those of you that don’t know TDI, you’re very well. We are a consultancy company that focuses on responsible sourcing and on helping businesses to unlock sustainability. As we say in the catchphrase, to work with businesses around the world in order to help them to reach their sustainability goals, particularly around the sourcing of materials and material supply chains, engaging with those supply chains in order to mitigate risks and maximise the positive outcomes for our people and planet. We’ve been partnering with a team of students from the Duke University – Nicholas School of the Environment to look at some sustainability considerations around sourcing bioplastics. Bioplastics are a very new upcoming resource of anguish. There’s a lot of buzz around sustainability. And as part of these students, teams’ master’s work, they have each team partners with an organisation that’s actually in the commercial sector and works on a research project. We have had 14 members in our research team over the past many months looking at these considerations around bioplastics and sustainable sourcing. After much effort, the research is coming to a close, and the cost is coming to a close. And so we’ve organised the webinar, and Patrice, who’s speaking on behalf of the student team, has kindly agreed to talk through some of the research findings with us. So over to you, Patrice, to say a few words of introduction, please. And then I will ask you some questions.

Patrice Barnett

I’m a student group of four of us, and we’ve been working really hard this last year to kind of understand the biobased plastic market and what drivers on how you can scale it sustainably. Last week, we just had our master’s presentation. It was a symposium where we talked through the findings that we wrote you wrote up in our report. And it’s been a really good experience, that I feel really lucky that my team decided we could discuss our findings.

Graham Lee

Right. So I am going to quiz you a little bit about your findings. We’re going to kind of run through some questions. I’m going to ask you all about what bioplastics are, what you learned about them what recommendations you have for a more sustainable future for the bioplastics supply chain, and there’s going to be time at the end for attendees to ask us questions as well. But if you have a burning question in the middle, we can be flexible enough to accommodate that. So start us off, please. What are biobased plastics?

Patrice Barnett

So bio-based plastics encompass a lot. We kind of like to do a little level setting just to make sure everyone’s on the same page with the terminology. So bio-based plastic usually refers to a plastic that’s made from some sort of biomaterial or biomass. When you’re thinking through how it’s different from traditional plastics. Traditional plastics usually come from fossil fuels and go through a chemical production base to create the plastic pellets that are used in product creation. Which are your typical plastic water bottles, plastic containers, and so forth? Whereas bio-based plastics really focus on using raw materials from agricultural goods. So you can think of that with corn sugar cane, there’s also the potential to use waste space. So it could be like waste cooking oil, and then that goes through a pre-production process of either biological or chemical fermentation, and it turns it into bio-based plastic pellets, and then that is used in the product creation phase. So bio-based plastics, they’re usually visually similar to traditional plastics, but they vary in technical capabilities. But for most bio-based plastics, you’ll see our water, our plastic water bottles, plastic containers, plastic utensils, and the key aspects of bio-based plastics. The selling point that everyone loves to talk about is their end of life, where their end of life allows them to be compostable allows them to be recycled. Not all of them, but most, and then, usually, when people talk about bio-based plastics, they’re thinking of the traditional PLA, which is a type of bio-based plastic or PHA, which is another type. And the main difference between these two is just that, chemical processing that pre-production I was talking about. And that chemical processing changes up, like the food service industry as a single-use, most bioplastics are really durable goods.

Graham Lee

So what was your research focused on? What was the kind of central research question that you were looking at? With bio blaster bio-based plastics?

Patrice Barnett

So when we started this off, the big question that came to us with you came to us with was this question of whether there is a market for waste-based bioplastic, waste-based bio-based plastics terminology here. And when we were diving into that, that’s when we were looking to see in that value chain, that feedstock could it be made from waste feedstock? And in this research that we did, we ended up finding and changing along the way to look instead of just at waist biobased plastic, but looking more at the market in total and what was available of just biobased Boston. One thing that I liked to talk about and that I found interesting was if we just look at some numbers, so single-use plastic it’s about 300 million tonnes of plastic waste produced yearly and about half of that. So about 3 million tonnes of plastic waste produce yearly, and then about half of that is single-use, and there is such a low recyclability rate of single-use plastic that this idea of diving into bio-based plastics, which could increase this recyclability, this compostability the sustainability is a really hot button topic. So when we were looking at waste space and bioplastics, we knew that there weren’t there wasn’t as big of a market as we thought available there. So that’s why we transitioned to looking more at bio-based plastics in total. And as I mentioned, the recyclability rate, it’s really between 5% to 6% of traditional plastics. So this is just a really emerging market that has been growing that has been a good source to dive into, and it’s been really interesting to see some of the conversations that have been happening in that space.

Graham Lee

Your research focus was essentially on sustainability. The potential of via plastic was awesome to me. What do we really mean by sustainability when we talk about bioplastics? You know, what is a sustainable bioplastics supply chain, what does it look like, and how can it become a reality? Why is this such an important topic of research, and what was your approach to it and trying to find some answers to those questions?

Patrice Barnett

To your point, it’s so important because of that number, right? The 300 million tonnes of plastic waste produced. You’ve heard those stories about in the Pacific Ocean, there’s the toxic Island, right where they’re hot topic of like save the turtles, don’t buy plastic straws, when really, in the consumer’s mind of reducing our consumption and use of traditional plastic products. And we thought it was really important to do this work of figuring out we hear the term bio-based plastic, we see materials that are available, but why hasn’t it become more mainstream? Why don’t we see larger consumer packaging goods companies producing bio-based products, when you walk into the store and you’re trying to buy a two-litre soda bottle, right? Why aren’t you automatically thinking, yes, this is biobased and possibly great? Those ideas that it’s not as prevalent in our everyday lives is why we really thought this was important, and we really wanted to just understand how producers are the ones who are creating these bio-based plastics, how they are thinking and defining bio-based plastics, and then your buyers or large consumer packaged goods, companies that are creating products and that product creation phase, like why they either are buying it maybe in smaller quantity or not. And they’re not creating products. We wanted to understand the relationship between them. And then we also were just super curious about why so much plastic ends up in the landfill. Is that something that can be mitigated with bio-based plastics?

Graham Lee

That’s the consideration of what’s going out. So what’s going in one of the people making bioplastics out?

Patrice Barnett

Yes. So when thinking about bioplastics, most bioplastics are made, as I mentioned, like a raw material that is a biomass of some sort. So you have different generations of feedstock, is what we call it. And in our research, we saw that the market it’s broken up into three different large buckets. You have your first-generation feedstock, second-generation feedstock and then third generation, and in your first-generation feedstock, that is your typical corn starch or sugar cane. It’s usually that raw material that you would get from an agricultural resource that’s grown on a farm, right? And it’s prevalent that you’ll notice I mentioned briefly at the beginning, like PLA, but a type of plastic, most of that is made from the first generation. The first generation also tends to be cheaper than the others, and it’s more available, and then you have your second gen from the feedstock. That is your typical waste material. So you could use waste cooking oil, or corn stover, which is a byproduct of the corn product. So you can use that in making a different type of plastic, a different type of bio-based plastic, and then that is usually a little more expensive, and availability starts to go down. And then you have your third generation, which we like to call a war novel. So this is where I would say researchers truly are pushing the boundaries of what can become bio-based plastic. And so, in that case, we’ve seen studies about algae and different types of seaweed being used to create bio-based plastics. And unfortunately, as you can guess, as you can probably guess, that is more expensive, and the availability of the product is really, really small. So when you’re looking at what goes into it, they’re really trying to figure out and trying to learn how much you want to spend for it versus how available the product is and whether it is scalable. And then what are the individual components that are stopping you from hitting any of your company targets, depending on if you’re a producer buyer?

Graham Lee

So you’ve started touching on some of the obstacles there. Let’s explore that a little bit more. I mean, what are the big issues that are stopping bioplastic from being everywhere in the shops? Like you say what’s, what’s blocking this from kind of taking off in a big way right now?

Patrice Barnett

So one of the big things that are blocking it, it’s this thought of food and plastic competition. First-generation plastics are typically made from a raw material that’s an agricultural resource and that has people worried that there is food competition there. Then there’s usually a lack of scale also when it comes to bio-based plastics. So because it’s, it requires a lot of land to be made in the first generation, then you have that constraint. In the second generation with waste-based products, you have the constraint of only as much as the raw material is produced. You can use it as a waste. And then it’s kind of more expensive. So another component is the expense compared to traditional plastics. There’s a lot here. And then there’s confusing terminology. So I’m sure everyone that’s listening has heard us bounce between the terms bio-plastic or bio-based plastic. They have different connotations and different definitions. Although consumers, when walking into a store, are not looking to buy a product and stand there for 10 minutes googling: What does this mean? What does this mean? It’s on the packaging. So there’s really confusing terminology in this space that I think prevents companies from seeing the value in investing in a product if a consumer doesn’t understand that value. And then, the end of life, right, so we talked briefly, that we thought that was really important to research. And one concern with end life is if bio-based plastics aren’t recycled or composted correctly, then they can be sent to a landfill, and if they decompose there, it’s an aerobic environment. And that can lead to methane emissions. And then you can also have potential contaminants in the recycling system if you send bio-based plastics to traditional recycling systems. So it’s like all of those aspects combined. It kind of keeps bioplastics from scaling as much as we think they would.

Graham Lee

Those all sound like quite a kind of technical engineering challenges or consumer relations challenges, except for this thing about competition with food. How are we going to overcome this issue with the competition between plastics and also biofuels in the next step and food production?

Patrice Barnett

So, unfortunately, we don’t have an answer. We thought that we would find the answer to this. So when we started this project, we decided to not only research what is in the literature, but we also thought that it would be really proud to talk to producers and buyers. So in the different stakeholder conversations with NGOs, certification organisations, producers producing new bio-based plastic pellets, and also buyers of these products who would be turning them into the products that a consumer would buy. And in all of these conversations, one of the interview questions you would ask was, “How do you get over this food competition? And we’ve seen two ends of the spectrum. We saw some of the people that we talked to use a common phrase of “It’s not food or bioplastics.” And the reason why they thought that it was bio-based plastics, they pick up the production which is 0.2% of the global arable land is used for this. And it’s only expected to grow to 0.6% in 2027. So, in that case, you’re thinking of it as you’re not taking a huge portion to scale bio-based plastics, and it’s not a competition. It can be used together there. Then on the other side of things, you have people talking about how, although it may seem it’s a small lab, use this also begs the question of how do you price the land and compete with other agricultural products for different communities who would potentially be using that land to create a different agricultural product to eat instead of an agricultural product that would be used for this. And there’s, there was a statistic that we saw that said, bio-based plastics would require 54% of the world’s total 2019 corn production to truly be scalable, and that’s huge. So in these conversations, it was two sides of the spectrum of there’s a potential to make it better and feasible. And again, that comes back to this confusion, right? Where is the answer? And one of the recommendations that we came to after having these conversation conversations was that going back to the feedstock table, the potential of using waste-based feedstock or investing in that market is a viable option because instead of traditional agricultural land being used just for bio-based plastics, waste-based feedstocks could use the waste of food-based corn and create a bio-based plastics, or waste products in that food stream to create these products instead of competing with lands. There’s also the thought of using degraded lands. So do you think degraded lands and farming these agricultural feedstocks help reduce that food competition argument. Because the land wouldn’t have been used for food anyway. Now you’re rejuvenating it by introducing these biobased materials that would be used in a bio-based plastic.

Graham Lee

We get to this question of scalability – is enough cooking oil and sugar kernel and palm kernels and sugar out there in order to make as significant amounts of bioplastics? What were your findings in that area?

Patrice Barnett

Yeah, I think for that specifically, it comes to the end of life. And I think really being able to make a case for waste-based plastics. I talked about it. It hits this idea of food and food production and bio-based plastic production, right or biofuels as well. But another real proponent for it is this end-of-life conversation. So the type of vehicle or biological process that happens to the raw material, whether these products end up, whether that’s a landfill, whether it’s compostable, whether it’s recyclable. That is important to understand you should what type of feedstock you should use. So as we mentioned when we started, and we were talking with producers and buyers, we started this conversation as really just looking at that part of the system of the value chain of saying what do producers want, what buyers want, what do what products are being created, but it was after those conversations that we realised this end of life conversation really dictates what type of products can be used, or what type of feedstock should be used in the creation. So with waste-based products, or waste-based feedstocks, most of those end up being compostable, and that can be either like home composted, so she has a back yard, and you have you’re doing this yourself, or it can be industrially composted, which gets sent to an industrial facility, and it gets composted there, and it also can be recycled. So, if that is the case, then it makes a strong case for waste-based bioproducts because you can now say, Well, we know that we want to reduce landfill waste, we want to increase our company’s sustainability. And to do so, we can make; we can make the valuable case the cost case for spending a little bit more on the youth waste-based feed streams. But as you mentioned, we weren’t able to focus our research solely on that just because the market is so nascent, and I think people are having these conversations and are starting to find this and are starting to dive in that direction. I can’t say for some of the interviews that we did, that were some of the conversations we had. Of, well, there could be a potential for this. If we move past, after we get past this research phase, we’ve kind of parsed out which feedstocks would be the best and what processes would be the best. So I do think it is a potentially viable option in the future is trying to iron out all of these. These next and then doing further research and be super interesting to see how this market grows as we move forward.

Graham Lee

And that’s something that I was really interested in from your research is really drawing those links between the stance of life and the end of life. And, you know, it’s not really a case of all plastics being equal or all feedstocks being equal. It matters for the entire system, what you put in at the start.

So the first question I can see here is what happens if you send a bio-plastic item to a traditional plastic recycling?

Patrice Barnett

So this gets a little into the technical details, but from what we saw, the reason why bio-based plastics can contaminate a recycling facility’s plant is the way that they decompose. So although bio-based plastics are visually similar to traditional plastics, their technical elements like some of the thermal properties they buried, so if you’re at the farmers market, and you get a plastic container, and you’re told that it is a PLA container, that plastic container may be one a little bit thinner and plastic and to keep it out in the sun or if you put it next to your stove. It may change, and that is just purely based on the chemical properties of that plastic. But if you take that compared to a traditional plastic container and put it next to the stove or leave it out in hot condition, they don’t like to hold its integrity. So when you’re sending it to a recycling plant, and you’re sending it to be either mechanically or chemically recycled, depending on the processes there, those technical aspects of the containers or of the bottles, whatever the material, make it more difficult to recycle than your traditional plastic containers and then something we also saw that was really interesting was with recycling plants. There is a lot more manual separation than you would expect. So you would send these large bundles of plastic there and the way that it gets sorted and recycled. It’s like through weight distribution, through cleaning through manual moving containers and bottles aside like it’s all those processes and adding that extra element of the chemical and the chemical properties of a biogas plastic make it difficult to recycle in the same way.

Graham Lee

Do you think consumers or producers have more power to promote bio-based plastics, and how can we encourage it?

Patrice Barnett

We would say we think consumers have a lot of power here. And this comes to the question of how you educate your consumers to understand what they’re asking for because I think there’s been a push for biobased plastics. One of the literature reviews that we looked at would take like a study, and they were asking in different countries, people’s experiences on, how do you define a bio-based plastic? What type of bio-based plastics do you buy? And then a really interesting question they asked was, would you purchase bio-based products if they were available? And there was an overwhelming percentage that said yes, they would. They would spend a little bit more to purchase it. But because terminology varies, you have terminology like compostable, which doesn’t necessarily mean home compostable or industrial compostable. You have biodegradability, which, depending on where you at, means a different thing. A bioplastic could mean that it’s not fully bio-based, and it could have some traditional plastic elements in it, like virgin plastic mixed with a biomaterial, and that’s a bioplastic, or you hear something say bio-based. So all of those terminologies make it difficult. So one of the recommendations that we made in our report was really educating consumers on terminology around bio-based plastics, and then, on the producer side, that could be filled with investments and partnerships with key stakeholders because this idea of being able to not only educate but being able to certify where a feedstock is coming from like is it full bio-based, involves communication and a partnership there that we think is a potential solution. So it’s not one or the other. It’s more what makes us complicated is it’s a mixture of people doing different bits and pieces that really will drive this market forward.

Graham Lee

So our next question is, what volume of bio-based products needs to be available in order to compete monetarily with non-traditional plastics, and when will that volume become available? There’s a question there about at what point this threshold is going to be reached. Where this whole kind of industry becomes really commercially viable? And how soon are we going to get it?

Patrice Barnett

So traditional plastic, when it’s produced, it’s able to be produced at a really low price. So then the product creation of it is financially viable. But for a bio-based plastic, when you take the raw materials, and you turn them into those bio-based plastic pellets, that conversion factor isn’t one-to-one. So traditionally, it’s like a one to 0.5 or 0.6, and unfortunately, that then means that you have to buy a lot more of this raw material to create a small amount of your biobased plastics. And that also, like that process, makes it really expensive. So when you look at like the technical process of trading a bio-based plastic, there are these different aspects that could be improved with processes that could be improved, that would overall make and reduce the cost price. One of the conversations we had with the producer talked about how they felt like there was an ability for them with their startup, and they talked about the technical aspect of the production of biobased plastics that they think they could bring down the price costs by at least half with just their new ability. And it’s like those effects. Building up together in the process would make it more cost competitive in terms of volume. That’s hard to say because it really depends on whether we are looking to produce product lines from it or whether you are looking to like completely replace traditional plastics. An example we like to give as we saw Coca-Cola had something called a plant-based bottle that they advertised, and it was popular for a while and a plant-based bottle. But it wasn’t fully bio-based, purely because of the technical components we mentioned of it being able to hold up, so it was more that they had virgin material mixed with bio-based material. So it’s that question of, like, are we looking to do that? Or are you looking to blend the two together? If you’re looking to completely replace, that’s a whole other question. So I don’t think there’s at least we didn’t find a specific answer for what would be the volume per se, but it’s really optimising those processes at each step of the bio-based plastic creation that would reduce the price, which would make it feasible to scale and bring to market.

Graham Lee

What about countries, in particular developing countries, that have banned single-use plastics? Because as the question-answer says, the problem with buying single-use plastics is where all of the alternative version materials come from. So do you think the bioplastics could help alleviate some of the supply crunches given the constraints in scaling bioplastics, and what’s the feasibility of a solution?

Patrice Barnett

That’s interesting. And this also makes the market even more interesting because we focused a lot of this research, really on the US, because it was what was available with the time training, like the scope of the project. So we didn’t spend a lot of time looking internationally per se, but one thing that we did talk about as the grill was countries that are banning single-use plastic, the idea of a fully bio-based plastic, presents a possible alternative. Now, back to the technical aspects. You don’t have a one-for-one trade-off just because bio-based plastics aren’t really used in durable goods. Again, going back to that thermal example, it might look the same, but it doesn’t physically act the same. So there is an argument to be made, and that could be used as an alternative, but at the same time, it needs development in the technical aspect to truly replace what we’re used to in the plastics market. An example we can also give in an exam is in a conversation we had; you’re talking with an airline company about why they don’t use bio-based plastics. When you order a drink, it’s in plastic containers. Why don’t you just use bioplastic there? The answer was that because they travel internationally, they have to abide by different regulations based on where they travel. So using and developing biobased plastics may not be feasible in some options because, as we mentioned, they may not be fully bio. It may not be a full product just from biomaterials. It may be a mixture of traditional fossil fuels. So it’s trying to navigate with different regulations that really make it hard, and one of the recommendations we did make was like standardising labelling, so, standardising labelling nationally, but ideally, internationally, if you are a large company, so that when you’re anywhere in the world, you know what you’re buying, you understand the components in it, and you know that it will meet those guidelines regulations from different areas.

Graham Lee

The next question is not specifically on bioplastics. I think it’s more of a general plastics question. So perhaps not quite your subject matter expertise. But let’s see how the separation of plastics is being planned on a large scale to increase the accessibility of recycling.

Patrice Barnett

The end-of-life capabilities that are available for traditional or bio-based plastics are lacking. So as it stands, like we gave the percentage at the beginning, I think 5% to 6% of the plastic is really being recycled, which is not a great number. And the main reason for that is because if you have food contaminants in a plastic container, that’s really hard for the recycling companies to clean off and then recycle. So it decreases the value for them, and they no longer want to use it. And just because it’s like such low margins, they have to go through so much product; they don’t put in the effort per se to do that extra because it doesn’t add value to the end product. So when it looks when you think about the end of life for traditional plastics, it would really be helpful. To be investing in some of these larger scale manufacturing companies or larger scale recycling facilities or composting facilities. Well, more recycling facilities for traditional plastics, because you would want there to be an increased increase in activity in this market to increase the want to recycle from these larger scale recycling plants and companies. And I guess on the side of the bio-based plastic, in a similar sense, we really thought that increasing composting industrially industrial composting facilities would be helpful.

Graham Lee

Yes. No point in making a recyclable product and no one actually recycles it. Last question: Do bioplastics waste break down fully if they end up in the ocean, or can they still be a threat to wildlife.

Patrice Barnett

Yes. So you want to make sure they’re recycled or composted in the correct way. So the PLA we talked about, is described as being industrially compostable. But if you send that to a landfill, and it’s just sitting in a landfill, after a certain amount of time, it may decompose. But the way and in the environment that it is decomposing, it is not what we would consider sustainable. But in a similar vein, you wouldn’t want those products to end up in an oceanic environment. Just as it would be a disruption to the wildlife. Now, there are other plastic when you talk about like PHA that advertises themselves as being more like home compostable, and that idea is that if you’re putting it in the proper environment, it will decompose slowly and take for that environment, but it’s the same aspect. It’s the tested scenarios that make it compostable, and whether or not it’s sent to an ocean, that’s not somewhere we would want our plastics to be, even if it’s a bio-based plastic.

Graham Lee

You wouldn’t want them in the ocean in the first place, even if they biodegrade it. There’s that period of time while they’re biodegrading. And then also, even once their bio degraded didn’t just disappear, they turned into other chemicals. I don’t know if you’re aware of any studies of what those chemicals are going to do when the in the marine environment but certainly, any sort of uncontrolled release of those industrial chemicals carries the potential for marine for harmful marine animals.

Patrice Barnett

It would be interesting to see a study done or an expansion of even this project in the marine environment. And again, when we talked about just the scope of the project, we really focused on the US boundaries here, and more landfill compostable opportunities and challenges will be really introduced into what is available and what research is there on decomposition in a marine environemnt.

Graham Lee

Okay, well, there you go. So you and the rest of the team can all start internships.

Patrice Barnett

We’re all graduating, so we’re all here headed out into the real world, hopefully, to be making an impact in the same way that we tried to make an impact with our master’s project.

Graham Lee

We’ve got one more question. Does the location matter when trying to recycle or compost? For example, is there a difference that should be considered on the East Coast versus West Coast versus overseas?

Patrice Barnett

Yes, so that comes back down to the facilities that are available. So when we’re thinking nationally about composting facilities, those are information available regionally. And it’s really just the conversation of whether it is worth the trip.Is it cost-competitive for those facilities to put out the resources to get these products in those locations, and sometimes it’s not just because it’s too far to send it to a composting facility, sometimes the local collection and the separation of the product it’s not valuable to pay me enough to be biobased materials or bioplastics to actually separate them out and send to the recycling facility and pay that additional costs. So what, like overseas, East Coast, West Coast, all of those considerations come in when you’re looking at the market and looking at it through the lens of price because it may not be price competitive. And again, that comes right back down to why the recyclability rate is so small. It’s because the market is not profitable enough for a company to send it to a recycling facility when they’re not nationally located.

Graham Lee

And that brings us on to another really interesting question as well, which is, you know, how do those economics change when you move out of the States when you move out of Western Europe and into countries where the cost of labour is a lot lower, whereas you know, other costs a lot lower and you can actually look at much more low tech solutions for recycling, collection, sorting. Things that wouldn’t work in the West can actually work really well in those developing economies those developing economies who can be leaders in these sorts of innovation simply because the economics look slightly different. I’m glad we were able to squeeze in that last question. Thank you very much, Patrice, for your time, and all the best for the future.

Patrice Barnett

Thank you so much. Thank you, everyone, for jumping in on this conversation about bio-based plastics.

supply chain

supply chain

Re-defining legacy | Supporting companies and investors in achieving positive legacies in mining operations

3rd July 2025 supply chain

supply chain

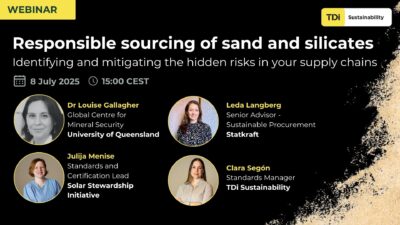

Responsible sourcing of sand and silicates | Identifying and mitigating the hidden risk in your supply chains

24th June 2025 supply chain

supply chain